Non Destructive Inspection

Eddy Current & Ultrasonic equipment

OUR NEWS :

Revolutionizing Aluminum Strip Quality : CMS’s Advanced Eddy Current Inspection System

CMS developed an Eddy Current system for the continuous inspection of aluminum strips for a customer in Europe. A guarantee of quality and confidence, this system is the third one they have acquired from us. It will enable them to increase productivity, improve product conformity, and minimize waste.

Main features of the equipment:

– Inspection of top and bottom surfaces for longitudinal and transverse cracks, inclusions, and scratches using more than 40 Eddy Current sensors (up to 64)

– Customized system to accommodate strip thicknesses from 2 to 13mm

– High inspection speeds of up to 60 m/min

– Capable of handling surface temperatures around 380°C at the exit of the hot rolling mill

– Floating Eddy Current inspection head allow the follow variation of the strip

– Automatic dynamic calibration to adjust all necessary parameters

– Dedicated software designed specifically for this application

– Real-time display of inspection results on the Eddy Current instrument

– Comprehensive inspection reports to ensure traceability

At CMS, all our systems are tailor-made to meet the unique needs of our customers and their specific applications. Our equipment is designed and manufactured by our skilled engineers, who are trained in the latest technologies.

Thanks to our extensive network of agents, we can study your projects and offer our solutions anywhere in the world !

Meet CMS at the European Conference on Non-Destructive Testing 2023 (ECNDT) – Stand 8 !

This year, the European Conference on Non-Destructive Testing (ECNDT) will be held in Lisbon, Portugal from July 3 to 7, 2023.

This international event shows the major importance of the NDT market and the diversity of its activities. The ECNDT 2023 conference is carefully planned to cover a wide range of topics, with a particular emphasis on technical and scientific aspects.

Come and meet the CONTROLE MESURE SYSTEMES team, booth #8 !

We will present you our different equipment for Non-Destructive Testing by Eddy Current and Ultrasonic for the inspection of tubes, bars, wires, billets, strips, rails, turned parts & forgings…

For more than 35 years, CMS has been developing a wide range of turnkey applications for defect detection, dimensional measurement, thickness measurement, conductivity measurement, material sorting, hot inspection, weld inspection…

The CMS team will answer all your requests for the realization of your projects of Non-Destructive Testing.

CMS, sponsor and exhibitor of COFREND Days 2023 – STAND 80 !

The COFREND Days are the biggest exhibition of the whole NDT professional sector. This year, this international exhibition will take place in Marseille (Palais Chanot) from June 6th to 8th 2023. CMS, sponsor of the event, will have the pleasure to welcome you STAND 80 !

For more than 35 years, CMS has been designing and manufacturing complete NDT systems using Eddy Current and Ultrasonic to detect defects, measure conductivity, perform dimensional measurements, perform thickness measurements, perform Material Sorting, perform hot inspection, control welds…

Come and discover our range of turnkey products for Non-Destructive Testing by Eddy Current and Ultrasonic, fully adaptable to your needs : high performance instruments, rotating heads, tanks & automated immersion benches, probes, accessories, software… Many products will be on display!

The CMS team will answer all your requests for the realization of your projects of Non-Destructive Testing.

The new head office of CONTROLE MESURE SYSTEMES opened its doors

For more than 30 years, CONTROLE MESURE SYSTEMES has been designing and manufacturing products and equipment for non-destructive testing by Eddy Current and Ultrasound and also combines these two methods of control on complete inspection benches. The company delivers its systems all over the world and works with major global groups.

After more than twenty years spent in its old premises and following the growth of its activity, CONTROLE MESURE SYSTEMES has finally moved into its new Burgundy premises.

This new building, whose construction started in December 2020, was financed with the help of the Burgundy Franche Comté region, the Feder as well as the Grand Chalon which subsidized the project up to 660 000€ for a total amount of the operation evaluated at 2,2 million euros.

Thanks to this investment, CONTROLE MESURE SYSTEMES will be able to manufacture and offer its customers new Non-destructive Testing systems at the cutting edge of innovation. The company’s production capacity will also be increased tenfold, as the new premises cover no less than 2,000m2, double the size of the old premises.

The company’s new address, effective since mid-August, is 6 rue des Lochés, 71000 Sevrey, France. Our sales department will be pleased to schedule visits with customers to show them the new building and the new working tools that CONTROLE MESURE SYSTEMES acquired.

CONTROLE MESURE SYSTEMES combine Eddy Current and Ultrasonic on complete inspection benches

CONTROLE MESURE SYSTEMES is a French company that has been designing and manufacturing Non-Destructive Testing systems for nearly 35 years.

Specialized in Eddy Current and Ultrasound, the company combines these 2 complementary methods in test benches that can be integrated directly on the production line. It also offers off-line control solutions.

CONTROLE MESURE SYSTEMES has recently delivered 2 complete inspection benches combining these 2 EC + US inspection methods for the inspection of welded rolled steel tubes with diameters ranging from 10 to 60 millimeters.

The two Eddy Current equipment with encircling coil installed on each bench allow to perform a grade sorting with sigma phase detection as well as a health check with the detection of surface and sub-surface point type defects. The reference defects used are transversal hole and external longitudinal notch.

The Ultrasonic control by rotating head (RotoUTscan) complements these EC controls and allows to carry out a material health control with the detection of internal and external defects and also allows to carry out dimensional measurements with a very high accuracy. The reference defects used are internal and external longitudinal and transverse notches with a depth of 5% WT.

On this bench, the integration of the Probus software, developed by Controle Mesure Systemes, will allow a real follow-up of the production. Probus collects analog signals from the N.D.T. equipment and is able to drive the line’s actuators. The software communicates directly with the control bench automatism of which it serves as a Human Machine Interface to control the sorting of the tubes and their marking. It also ensures the traceability of the production with the creation of inspection reports by products or batches.

In order to allow an even more advanced follow-up of the production, a second software called Probus Viewer Analyzer has been developed for the re visualization of the signals acquired during previous controls. The graphical options included in the software will allow the operator to perform a thorough analysis of each strip chart using zooms or cursors.

CONTROLE MESURE SYSTEMES is proud to offer turnkey Non-Destructive Testing systems integrating its own control equipment.

CONTROLE MESURE SYSTEMES should soon move into its new premises

After nearly 35 years of existence, CONTROLE MESURE SYSTEMES will soon move into its new offices, which is scheduled for delivery at the end of July.

This project, which cost nearly 2.2 million euros, was financed with the help of the Burgundy Franche-Comté region, the Feder and with the Grand Chalon for an amount of 660,000 euros of subsidies.

This new building will allow the company to develop its activity by designing and manufacturing new Non-destructive Testing systems at the cutting edge of technology.

The production capacity of CONTROLE MESURE SYSTEMES will also be increased thanks to this new premises, twice as large as the old ones. Indeed, the premises under construction will cover no less than 2,000 m2. All system construction activities (production, handling and assembly) will thus be able to take place in one and the same place, which will make it possible to design test benches and control lines up to 70 meters long.

After the opening of the company’s first subsidiary in the United States at the end of 2020, this new workspace will enable CONTROLE MESURE SYSTEMES to strengthen its leader position in the Non-destructive Testing market.

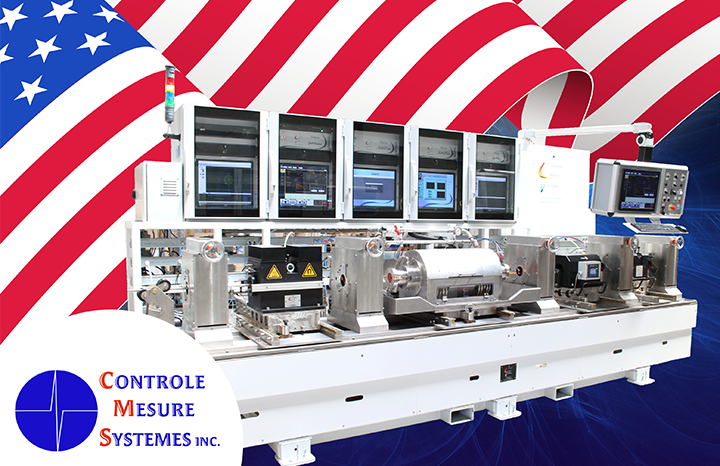

CONTROLE MESURE SYSTEMES opens its American Subsidiary

CONTROLE MESURE SYSTEMES (CMS) is an expert in Non-Destructive Testing since 1988. The company designs and manufactures its own Eddy Current and Ultrasonic equipment, and offers a wide range of products for industries such as Metal, Energy, Aeronautics, Automotive, Medical and many more.

Already represented by a network of agents in more than 15 countries, CMS is now aiming to develop the American market to answer the large need in NDT. After solidifying its presence in Mexico, CMS conducted market studies in the USA and started building a network of relationships with local stakeholders.

A local presence in the USA will guarantee great reactivity and efficient communication with the American customers.

After studying all the possibilities, CONTROLE MESURE SYSTEMES opened its sister company CONTROLE MESURE SYSTEMES Inc (CMS Inc) in December 2020, located in Long Island City, NY.

The manager of this new entity has been working in the United States for the past 10 years. With his professional experience and the extensive training he received from CMS France, he is starting this new challenge with great enthusiasm.

This exciting project, in addition to the construction of the new 20000ft² headquarters in France, is critical to provide the best services and pursue CMS overall development.

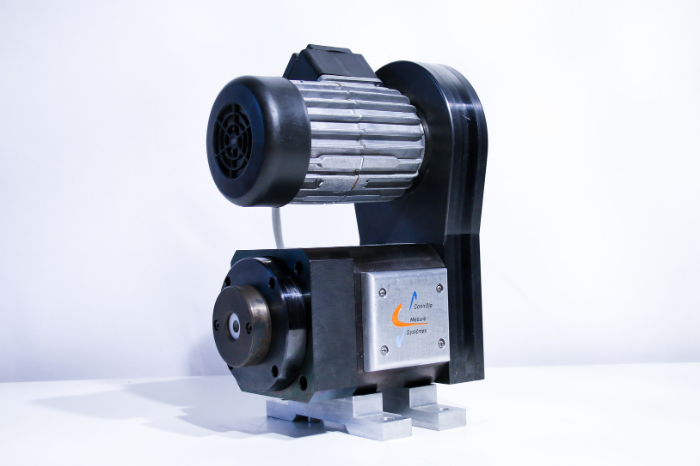

Controle Mesure Systemes offers instruments dedicated to the controle of wire and parts with small diameter

Controle Mesure Systemes is a French company that has been designing and manufacturing Non-destructive Testing systems for nearly 35 years. Specialized in Eddy Current and Ultrasound, the company integrate these 2 complementary methods in combined test benches.

Wishing to bring a control solution to each need for each and every customers, Controle Mesure Systemes has designed a rotating Eddy Current head (RotoETscan TRVC) dedicated to the control of wire and parts of small diameters (range from Ø 0.8 to 10 mm).

This system, which can be easily integrated on a control line, includes a cassette adapted to the diameter of the product. Eddy Current probes installed inside the cassette rotate at high speeds around the product (up to 18 000 rpm). This model allows the detection of longitudinal defects on wires, bars or unit parts with a very high inspection speed (up to 3m/s).

For the control of wire or continuous products, Controle Mesure Systemes also designs opening Eddy Current probes that allow to be inserted into the production line without having to cut or stop it.

These probes are very useful for the continuous control of butt-welded wire coils. The detected defects are punctual and transversal. Controle Mesure Systemes is always innovating to offer its customers efficient solutions adapted to their needs.

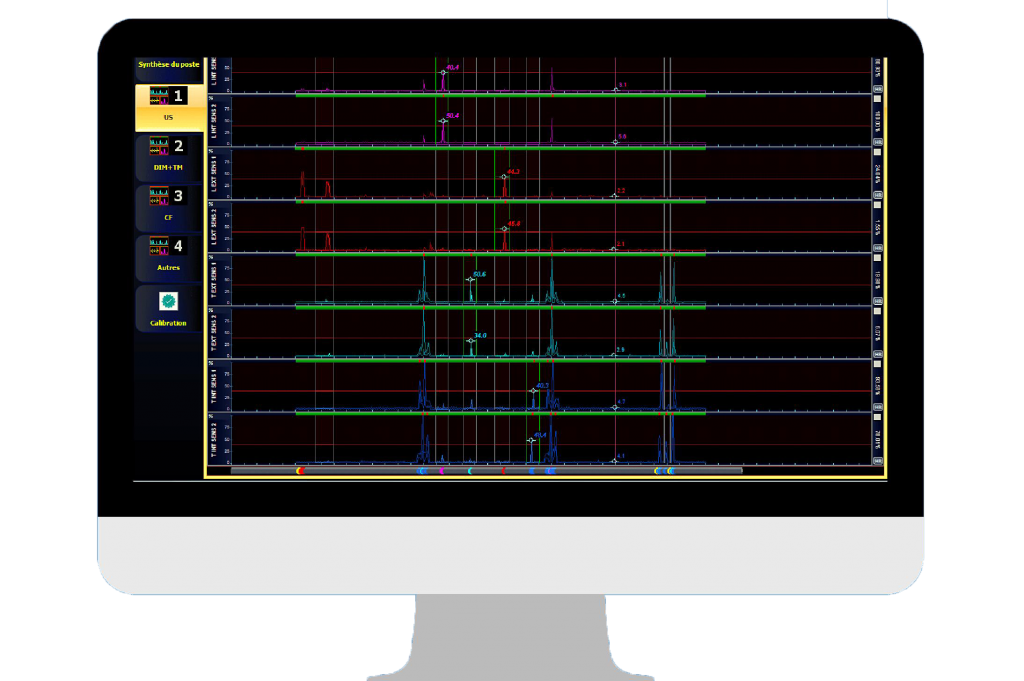

Probus : A smart software for Non-Destructive Testing

CONTROLE MESURE SYSTEMES has developed a software called Probus. It collects information provided by NDT equipment in order to display signals, analyzes them, makes a sorting decision and creates inspection reports. Probus is the decision-making center of the Non-destructive Testing line. It centralizes all the sensor data and is able to control the actuators of the test bench.

The main purpose of the Probus software is to ensure the traceability with the creation of either an individual product or a batch inspection report. They can list the detected defects and their locations and serve as proof of control.

Alarm thresholds can be set up for each channel. When a signal triggers the alarm, the software displays it live and mark the product as defective.

Probus not only can handle several types of signals (Ultrasonic for flaw detection or dimensional measurement, Eddy Current), but also manage the good/bad sorting of the products and control the marking system.

The supervision software can be used with many other brands’ systems such as Ultrasonic and Eddy Current rotating heads, EC coil holders, magnetization/ demagnetization units, and many more !

Probus is able to read and use any analog signal, so CONTROLE MESURE SYSTEMES can easily integrate it on an obsolete inspection bench and take care of the revamping of the installation.

CONTROLE MESURE SYSTEMES is building its new head office

After more than twenty years in its current premises, CONTROLE MESURE SYSTEMES started the construction of the new ultra-modern head office at the end of 2020. The new premises will be located in Burgundy (Sevrey, France).

Financed with the help of the local region, the Feder and the city, this project will help CONTROLE MESURE SYSTEMES strengthening teams and hiring new talents. A developer will join the adventure in order to perfect our IT team, a designer will join the mechanical engineering office, and finally a marketing center will allow the brand to increase its communication and digital strategy.

This project will considerably increase CMS’s production capacity since the workspace will double. Every project stages (design, assembly, testing) will now be able to take place in a single location, allowing benches and control lines up to 70m long.

The company also wished to emphasize its ecological commitment. A 60-meter long water storage and retention basin will help preserve the local ecosystem. In addition, an area at the rear of the building will be developed to meet environmental standards and preserve local wildlife.

CONTROLE MESURE SYSTEMES has invested nearly 3 millions euros in this project to keep up with its tremendous growth.

The director of the company stated: “CMS is a family business, I am delighted to see this project evolve and I cannot wait to discover all the possibilities this new space will offer us.”

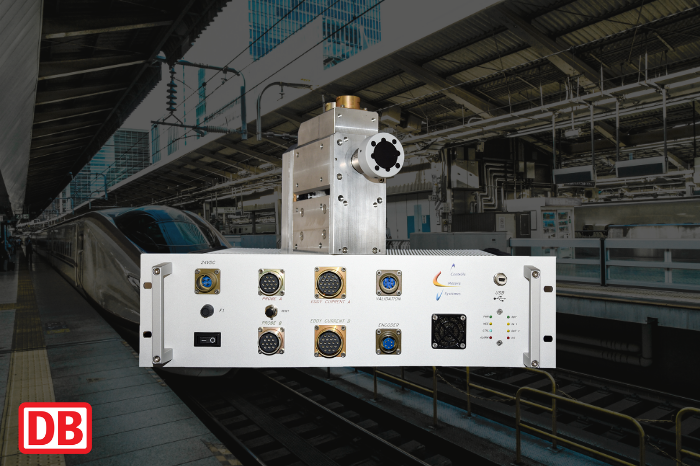

CONTROLE MESURE SYSTEMES is proud to receive the Deutsche Bahn certification for rail control !

For several years, CMS has been working on an innovative system for rail inspection, composed of custom rotating probes. The idea is simple: two probes are placed on either side of the train. They are rotating at a very high speed right above the contact area between the wheel and the rail, to detect possible surface/fatigue defects.

For nearly 3 years, we have been working on the mechanical and technical improvement of the device. The rail surface being curved, an electronic system has been designed to compensate for the distance variation between the rail and the EC rotating probe. CONTROLE MESURE SYSTEMES also worked on easing up the calibration of the device so it could show the operator the defect’s depths. The robustness of the system was a key element of the development since the instrument is subject to many wear factors (dust, friction, humidity, cold) in its working environment.

When defects are identified, the control system sends the information to the supervision of the train that operates a rail grinding device. After each grinding pass, the rails are being checked again to make sure the defects have been eliminated by the grinding operation. These steps are repeated as many times as necessary.

The certification issued by Deutsche Bahn is one of the most comprehensive in the industry. It is required in several countries to have access to the rail inspection market. CONTROLE MESURE SYSTEMES and its partner has carried out series of tests with the organization since 2017, to successfully pass all the accreditation stages. Thanks to this hard work, CMS is able to work in a multitude of countries with an efficient and certified system.

With a 30-year expertise in Eddy Current and Ultrasonic inspections,

CONTROLE MESURE SYSTEMES provides high quality Non-destructive Testing solutions

for industrial applications all over the world.

About us

Types of inspection

Service & support

Corporate Office

CONTROLE MESURE SYSTEMES

6 rue des Lochés

71100 Sevrey – FRANCE

+33 3 85 94 14 14

contactcms@cmsndt.com

CONTROLE MESURE SYSTEMES Inc.

67 West St. Suite 401

Brooklyn, NY 11222

+1 (347) 684-9941

sales@cmsndt.com